ITES Shenzhen International Industrial Manufacturing Technology and Equipment Exhibition and the 22nd Shenzhen Machinery Exhibition will be held from March 30 to April 2, 2021 at Shenzhen International Convention and Exhibition Center (Bao'an New Hall), as the largest advanced exhibition in southern China. One of the manufacturing technology and high-end equipment exhibitions, the exhibition is based in the Pearl River Delta and faces the world. It is committed to creating a world-class industrial event that radiates at home and abroad, and aims to provide a solid force for technological progress, business cooperation and industrial development in the global industrial market.

As a supplier of comprehensive electrical automation, intelligent products and solutions, UniMAT will bring industrial IoT products and solutions, industrial automation products and solutions to this exhibition with the theme of "Internet of Things, Intelligent Control of the Future". Invite you to visit the booth to visit and exchange!

Exhibition name: ITES Shenzhen International Industrial Manufacturing Technology and Equipment Exhibition and SIMM Shenzhen Machinery Exhibition

Date: March 30-April 2, 2021

Venue: Shenzhen International Convention and Exhibition Center (Bao'an New Hall)

Booth No.: 9-A34

1. IoT Gateway - UBox

UBox is a data acquisition terminal product in the overall solution of UniMAT Industrial Internet of Things. It is used to connect PLCs, inverters and instruments and other equipment, realize networking through WAN, WIFI, and 4G, and transmit device data to UniMAT cloud platform.

2. IoT screen-UH500W series HMI

UH500W series human-machine interface is a brand-new IoT HMI launched by UniMAT, available in 7-inch and 10-inch sizes. This series of man-machine interface supports the function of Internet of Things, supports remote uploading and downloading of equipment programs, timely push of fault information on multiple platforms, and functions such as mobile phone and web page to check the operating status of the screen anytime, anywhere.

1. X series PLC

In response to the company's efforts in the domestic market in recent years, it has integrated the characteristics of customer needs in the motion control industry, and at the same time, in order to respond to customers' personalized needs more quickly, UniMAT has launched a new X series PLC. This series of PLC is a brand-new independent research and development and production, motion control function type PLC with powerful motion control function. This series perfectly combines the advantages of the expansion capability of the old products, and is the first choice for OEM equipment, small projects, IoT smart devices and other control systems.

X series PLC includes X1 economic CPU, X2 standard CPU, X relay CPU, X3 enhanced CPU, X5 motion control CPU and expansion modules, BD expansion board.

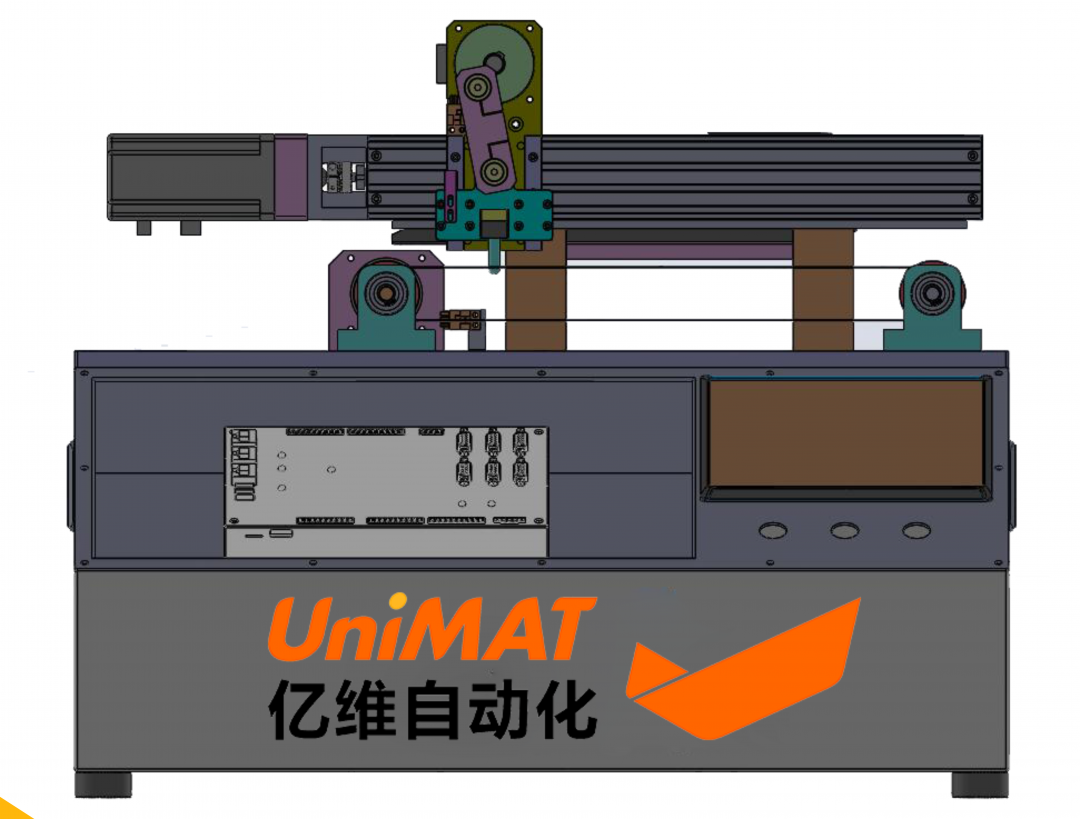

2. Flying shear platform

The flying shearing platform is composed of UniMAT motion controller, EtherCAT servo, touch screen UH407 and related mechanical structures, etc. It simulates the application site of fixed-length cutting of pipes and profiles. The belt is driven by the servo motor A, which simulates the continuous output of the pipe in the field; the module simulates the tool holder, which is driven by the servo motor B; the crankshaft simulates the cutter. Driven by servo motor C. During the running shear motion, the belt rotates continuously, and the module is accelerated to reach the running speed of the belt. After the speed is synchronized, the crankshaft motor runs at a certain angle, simulating the cutting action of the cutter; after the cutting is completed, the module table returns at a high speed The origin, waiting for the next cut, and so on.

System Features:

丨High precision

丨High work efficiency

丨The electrical power is relatively reduced, and the cost performance is high

3. Sync Platform

In printing machinery, textile machinery and other fields, multi-motor synchronization is widely used. The system simulates the requirements of speed synchronization, position synchronization and other working conditions, and the synchronization displacement range is small. Common synchronous control methods such as master-slave follow mode, this method is based on the position and speed feedback of the spindle, as the adjustment target value of the slave axis, through the data operation of the UniMAT X series motion control CPU, so as to control the slave axis.

System Features:

丨 Faster adjustment response

丨Closed-loop control, high synchronization accuracy.

丨Through the UniMAT servo host computer software, the parameters of the master and slave servo drives are easily adjusted.