Overview

PLC controllers monitors input, performs logical operations, and controls output devices in a programmed manner, thereby realizing automated control of mechanical equipment and production processes, and is used in various industries, including: manufacturing, building automation, traffic control, new energy, municipal facilities, etc.

Unimat has been focusing on industry automation for 20 years and insists on independent research and development. Currently, it has launched the cost-effective UN120 series industrial plc , the small-sized UN200 series industrial plc , the self-matching UN SMART series industrial plc , the modularly designed UN300 series industrial plc , and the UN1200 series industrial plc that is seamlessly compatible with Siemens.

UN Series PLC Controllers

Perfectly compatible with Siemens PLC

Industrial grade/Strong and durable

High cost-effectiveness

Rich product range:Mini/Micro/Medium/Large

Easy to maintain

Reliable plc logic controller

What is programmable logic controller(plc)?

A programmable logic controller(plc) is a digital operation electronic system designed for use in industrial environments.

It uses a programmable memory to store and execute logic operations, sequence control, timing, counting and arithmetic operations, and controls various types of machinery or production processes through digital and analog inputs and outputs.

PLC controllers and its related peripherals should be designed to be easy to form an integral part of the industrial control system and easy to expand its functions.

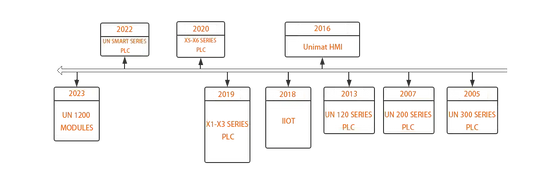

Unimat's history of developing PLC controllers

Unimat was founded in 2005. Its first self-developed product was the UN300 series PLC. PLC300 adopts a modular design. Users can add and change modules according to their needs. It is very flexible and can meet different control needs. After it was launched on the market, it was well received by the market. Later in 2007, the UN 200 series PLC was launched. PLC200 is a small-sized PLC with compact size, space saving, simplified overall layout, and easy installation. Due to its small size, there are fewer installation accessories and connecting cables, which reduces the overall cost, but the performance is still strong. In the subsequent development process, Unimat has also continuously enriched its product line and launched a series of products that meet customer needs and are popular in the market, including: UN 1200 PLC, UN 120 PLC, HMI, all-in-one machine, etc. Among them, PLC1200 is seamlessly compatible with S7 1200, affordable, and very popular.

Advantages and Disadvantages of Using industrial plc

Industrial plc has a relatively long history of development, and various manufacturers have also improved and upgraded it in the process of product renewal, but there are still some common advantages and disadvantages in the use of PLC:

Unimat PLC controllers Advantages:

Unimat has been focusing on the industrial automation industry for 20 years and has invested a lot of R&D funds in the development of PLC. Our PLC can almost meet the different needs of customers and can be designed individually according to customer needs. In the existing PLC product series, each series has targeted solutions to industry pain points, such as our PLC300 adopts a modular design, PL 200 is small in size, and the PL 1200 series can be seamlessly compatible with S71200, etc.

Industrial plc application:

PLC is widely and deeply applied in the field of industrial automation, bringing revolutionary changes to all walks of life. The following are seven common areas:

Manufacturing: PLC shines in production line control. From assembly to packaging, every step is accurate and correct, improving efficiency and flexibly responding to various production needs.

Automation process: Whether it is chemical, electricity or water treatment, PLC can intelligently execute control operations through sensor input to make the process more stable.

Building automation: lighting, air conditioning, elevators, PLC is available, realizing intelligent building management, energy saving and consumption reduction, and improving living comfort.

Transportation and logistics: traffic signals, rail transit, logistics and warehousing, PLC makes transportation more efficient and safe.

Agricultural automation: greenhouse control, irrigation system, PLC helps modern agriculture, and technology changes agricultural ecology.

Energy management: power distribution, grid control, PLC plays a big role in energy management and promotes the development of green energy.

How to choose a PLC controllers?

When you need a PLC, what can you consider to choose the right PLC?

Home page, you need to clearly understand the needs of the control system, including the number and type of equipment to be controlled, the complexity of the control logic, etc.

Secondly, consider the environmental factors of using the PLC;

Third, consider the output type of the PLC, and other factors include storage capacity, response time, networking function, manufacturer's technical support and service, cost-effectiveness, and special needs of some special industries.

If you are not sure, you are also welcome to consult our engineers online, and we will assist you in choosing the right PLC.

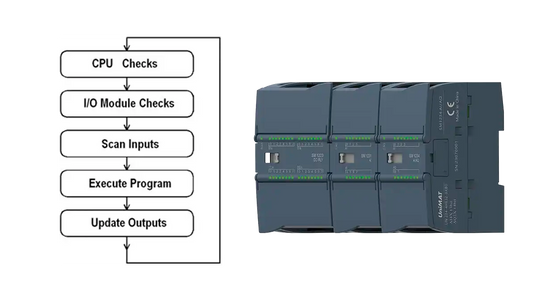

How does industrial plc work?

Industrial plc uses a cyclic scanning mode. In PLC, user programs are stored in order. The CPU starts to execute the program from the first instruction until it encounters the end character and returns to the first instruction, and repeats this cycle over and over again.The scanning process of PLC is divided into several stages: internal processing, communication operation, program input processing, program execution, and program output. The time required for a full process scan is called a scanning cycle. When the PLC is in a stopped state, only internal processing and communication operation services are performed. When the PLC is in a running state, it keeps scanning from internal processing, communication operation, program input, program execution, and program output.