With the rapid development of electronic technology, PLC is more and more widely used in building materials production line. On the basis of accepting the control form of PLC as the core, due to the market competition and the different cognition of domestic customers, it not only requires the PLC to be as stable as possible, but also requires the cost of the whole control system to be as low as possible. Basically, it is a contradiction at home. This article mainly discusses the solution and application plan of this problem.

Two. Abstract:

By describing the successful case of the application of PLC module developed independently by Shenzhen UniMAT Automation Technology Co., Ltd. in concrete mixing station and aerated block production line to realize the automation of building material production line, the application scheme of UniMAT module in building material production line is put forward, and the stability of UniMAT module in practical application is also discussed. Performance and price advantage.

Three, key words:

Concrete mixing station, aerated block, S7-200, S7-300, keyboard scanning, weighing ingredients.

1. Introduction

We will continue to discuss the concrete mixing plant as a kind of building materials industry, because it has the following characteristics as a whole:

A, the production environment is bad, the dust is large, and the vibration is increased.

B belongs to process control, logic flow is much, logic of equipment is relatively complex.

C. Most of them are equipped with weighing and batching technology, which requires high precision and efficiency, and the equipment runs quickly.

D, the customer's equipment maintenance ability is low, the control system and electrical equipment stability requirements are higher.

E, customers request investment as low as possible.

The self-developed modules compatible with Siemens S7-200 and S7-300 are applied to the concrete mixing station control system and the aerated block production line control system respectively in the building materials production line. In this case, UniMAT PLC fully demonstrates its strong stability and price advantage.

2, application plan

2.1 concrete mixing station control system

Concrete mixing station mainly realizes the measurement of raw materials such as sand, stone, cement, fly ash, water and additives, and feeds the mixer according to a certain set order, mixing for a period of time and discharging. The main characteristic of the production line is the difficulty of control.

A. Require high efficiency, equipment is intermittent operation, but the production efficiency as close as possible to the continuous operation;

B. High mixing accuracy. The national standard requires that the dynamic metering accuracy of sand and stone is less than 2% and the accuracy of powder and liquid materials is less than 1%. Especially for additives, the dosage of additives is sometimes 10 kg, and the error can not exceed 0.1 kg. This is still in the occasion where the vibration of mixer is especially large.

C. The requirements of production management are relatively high. It requires full recording of production data, including any manual operation by the user. All manual operation signals are required to enter the microcomputer through PLC.

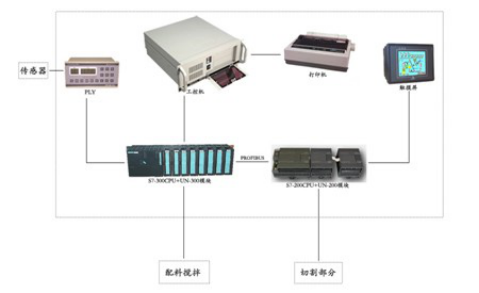

The I/O points of the whole system are about 120, and the DI and DO points are almost the same. In order to solve the above problems, we adopt 214 CPU modules of Siemens S7-200 PLC. The remaining I/O modules and the AI modules used for moisture content measurement adopt the series of 100 million-dimensional UN200. The batching measurement adopts the batching control instrument PLY600 developed by Shandong Boshuo himself. Realization. In the UN200 module, the 8DI/8DO digital module is used as the keyboard scanning module to collect the signal of manual operation. The system structure is as follows:

2.2 air entraining block production line control system

Aerated block production line is also a harsh application environment, the control system of dust resistance and other aspects of the test is very strict. In the past, we mostly used Siemens S7-300 PLC, the overall cost of the system is high, many users reflect that they want to reduce the price, but ultimately accept the high price, contact with billion-dimensional modules, after testing, we decided to use UN-300 series of modules instead of the corresponding AI, DI, DO modules, using Siemens 313C-2DP CPU, using the power module of 100 million dimensions, the system structure is as follows:

3. Conclusion

The construction material production line of Shandong Bo Electronics Co., Ltd. has been integrated with the billion-dimension module for five years. Its PLC performance is stable and the quality is reliable. At the same time, our scheme has been recognized by more and more customers, which fully meets the needs of the vast number of building material customers. The practical application shows that the billion-dimension module greatly improves the production of building materials. Online production efficiency and economic benefits.