First, preface

The press of several production lines in an automobile factory is the equipment manufactured by German SCHULER Press Company in the 1990s. The S5 series PLC of SIEMENS Company is used to realize the core control and critical protection of the punching machine tool. It has been continuously produced for more than ten years since it was put into use. At present, the Siemens S5 control system used by the press company has been more stringent. Serious aging, rising failure rate, and many electrical control equipment due to a long period of time, Siemens no longer production and supply, spare parts supply exists a great risk, if not changed in time, will press maintenance and normal high-efficiency production bring great hidden dangers, in order to solve the maintenance problems faced by the press, will look at The previously used Siemens S5 control system was upgraded to the widely used Siemens S7 control system to fully ensure the normal and efficient operation of the press.

Two, system overview

With China's accession to WTO, foreign automobile factories have invested in China to build factories. There are many kinds of automobiles with different styles. The development of stamping production enterprises is more and more closely linked with the automobile industry. The object of this transformation is 600 tonnage closed punching machine. The schematic diagram of system control is as follows. When the punching machine is working, the flywheel is driven by a motor through a belt wheel, and the crank-slider mechanism is driven by a gear pair and a clutch. The rotating motion of the flywheel is converted into the up-down motion of the slider to complete the stamping of the workpiece. The slider moves from the highest point to the lowest point to complete the stamping of the workpiece, and then returns to the highest point to break the clutch and complete a working cycle. In order to adjust the size of the slider on the workpiece in order to better complete the stamping of the workpiece, an air cushion is installed under the moving table, and the press is pressed at the prescribed pressure by adjusting the pressure of the compressed air inside the air cushion. In the stamping process, because the weight of the slider will have an important impact on the motion of the whole system, a balancing device is used to hold the slider with compressed air, so that the weight of the slider is zero, and the power of the slider movement is completely provided by the flywheel. Thus avoiding the influence of slider weight on the system. Each press can replace different die stamping different workpieces, in the replacement of the mold will be put down the air cushion, the slider mounted on the punch unlocked, placed on the moving table above the die, slider open to the highest point, and then through the moving table to open the mold, the new mold into.

The system consists of the following parts:

1. the core control system of punching machine is made up of S5-155U.

2. peripheral devices driven by S5 I/O

3. the upper monitoring and data management system is composed of WF470.

4. parallel encoder monitoring system slider, air cushion height, cam angle

5. WF715 constitutes a cam safety control system.

Three, system requirements

1) Extending the service life of the machine - because the press is the key equipment in the automobile production line, the normal or not of the equipment is directly related to the operation efficiency of the entire automobile production line, and the equipment of a single press is expensive. Since the life of the mechanical part of the press is about 50 years, and the life of the electrical part is generally only about 15 years, so in the life of the press about three times to reform the electrical equipment.

2) Reduce the cost of spare parts, good maintainability - in order to achieve good maintainability after the system transformation, a variety of hardware modules choose standardized series, should be selected with good development prospects of technology products, so as to ensure the long-term supply of spare parts in the future. The software is modified on the basis of the original S5 program, which not only guarantees the consistency of the reformed system, but also customizes the control function according to the user's requirements, and adds necessary annotations to ensure the readability of the program code. Therefore, there is no problem in the maintenance aspect. All kinds of development documents are well preserved and archived regularly in time to ensure the readability of the program code. The maintainability of software;

3) Quick replacement reduces downtime by only 4 weeks - in order to save time and labor in site construction, shorten downtime and reduce the impact on production. Prepare for the transformation: which needs to be replaced and which remains in the system, and make a reasonable arrangement and division to prevent blindly expanding the scope of transformation and omission of transformation projects. All wiring and the control points in the program are exactly the same.

4) All-Chinese operation interface and powerful diagnostic system-all-Chinese operation interface make it easy for operators to understand equipment status, modify process parameters, provide output query, and facilitate production scheduling. At the same time, the fault and alarm information are displayed intuitively in the upper computer graphically, and the communication status of each node in the system is displayed.

5) Customize the control function according to the user's requirement - while keeping the original operation mode unchanged, add the corresponding monitoring function according to the actual needs of the site.

Four. System design

1, design plan

As the press is the key equipment in the automobile production line, whether the equipment is normal or not is directly related to the operation efficiency of the entire automobile production line, and the equipment of a single press is expensive. Therefore, in the process of transformation, the requirement is 100% safety and 100% success rate. In view of the above situation, the following plans are adopted in the whole project transformation process:

1) in the process of the whole system transformation, debug the software first and then rebuild the electrical equipment.

In order to reduce the transformation risk of the whole project, all S5 equipments are not moved at first, and a PROFIBUS communication card is added to the S5 system. All the equipment signals in the S5 system are transmitted to the S7 400 CPU through PROFIBUS communication. The S7 400 CPU replaces the S5 control CPU. The control program of a device runs in S7 400, and the external control signals are all driven by the template of S5.

In the whole project implementation process, by adding a switching program in S5, the S7, S5 system can be freely switched to control the machine only by modifying the parameters, and the whole system replacement process can be completed within three hours, to achieve no risk transformation.

2) The whole electrical equipment renovation follows the principle of systematic upgrading, according to the press control process requirements, S5 controller is upgraded to S7-400F controller to increase the safety protection function.

The safety control system is a control system specially used for interlocking in dangerous places and emergency parking. The essential difference between PLC and ordinary process control is that its function is to make the device stop safely under the condition of accident and failure (including the device accident and the control system itself failure), to avoid the damage to the personnel of the device and to the environment. If a critical application scenario occurs, the controller can enter a user-defined security state to execute the downtime program in a predetermined order, and then provide the user with diagnostic data information reports.

For user's convenience in equipment maintenance, the modification process ensures that all program structures, electrical wiring, and instructions are substantially consistent with the original system, and that all modifications are detailed and annotated. In addition, all programs, variable tables are added in Chinese annotation, to bring convenience to maintenance personnel.

3) The monitoring screen uses a WINCC data monitoring server as the main monitoring computer of the whole system and a touch screen with an electronic disk as the machine monitoring interface.

Because the vibration of the press will cause very serious damage to the hard disk of the computer, it is required that the monitoring computer installed on the machine can not have hard disk, and the control process of the whole production line requires that all data management must be unified by the computer. In order to solve the above contradictions, the whole system is managed by two computers. A BOX PC is installed in the electric control cabinet to realize the data management of the whole system. The management software is implemented by the Siemens monitoring software WINCC, and the operating system adopts the stable and reliable WINDOWS 2000. Another computer uses Microsoft's WINCE as its operating system. The entire computer does not have a hard disk, and the data is stored on a 2G electronic disk.

Using the special monitoring software NETC@P imported from Germany, the WINCC software on BOX PC is monitored remotely. Compared with other remote control software, NetC@p software specializes in real-time services, and is easy to control the operation process. The system runs out of software in the form of a graphical display card, so all applications are displayed on a personal digital assistant or mobile tablet computer without additional software programming. NetC@p is responsible for analysis and adjustment. The software installed on the host is like a terminal emulator that packages images, mouse and keyboard information onto Ethernet for slave use. The slave is often used as a client application or mobile terminal (with Windows CE as the operating system), and on the slave, the NetC@p application will automatically start running. No other programs or devices are needed. Through a set network, or ISDN and DSL network connection, only pre-set connection parameters, and input the system, that can easily achieve remote operation and analysis, significantly saving time and cost.

4) encoder is replaced by PROFIBUS DP bus structure encoder.

The original TTL level absolute encoder is replaced by an encoder with PROFIBUS DP interface. PROFIBUS DP network can provide 12Mb/s transmission rate and excellent anti-jamming ability, which makes the control accuracy and anti-jamming ability of the new system far stronger than the old system.

5) S7I/O module adopts distributed I/O system ET200M module, the module uses UNIMAT's UN 300 series module, and uses PROFIBUS DP bus structure between CPU and S7I/O module.

2, system configuration

The upgrade table of the whole automatic control equipment is as follows. The main electrical control equipment of the automation will be replaced by a new control system.

After modification, the electrical diagram of the system is as follows:

3, control system function upgrade

1) adopt S7 400F fail safe controller and signal module.

The controller of the system adopts Siemens S7 400F fault-safe controller and compiles the internal integrated cam control software of S7 400 to realize the cam control. It replaces the original cam controller WF715. While increasing the control flexibility, the electronic cam and the electronic cam are controlled by the safety function module provided by the fault-safe controller. Cam encoder communication carries out safety monitoring to ensure system safety and avoid damage to operators.

2) data exchange between S7 system and computer using Ethernet.

Ethernet communication module CP443 is added in the system to exchange data between Ethernet and the upper computer of the whole system. At the same time, the interface is provided for the networking of the whole production line. The operation of any press in the unit where the press is located can be monitored on each press, which brings convenience for maintenance.

3) Using the special remote monitoring software NETC@P, the data exchange between the press display terminal (slave) and the PC BOX (host) is realized through Ethernet.

In order to avoid the damage to the computer caused by the working vibration of the press, two computers are used to complete the monitoring of the whole system. One uses a high-reliability Siemens PC BOX industrial computer as a server to store data and install all the control software. The other runs a special operating system as a client display terminal. Remote access to the server; an electronic disk is installed on the client's computer without any moving parts to avoid damage to the computer's life due to the vibration of the press.

The host can identify all registered slave machines and assign only one operation right to a slave at a time. When the command is entered on the console in the control room, a red or green traffic signal-like light is lit. Avoid simultaneous operation or erroneous operation. Operators can also pre-set the host computer to decide whether it is the host computer that makes the decision whenever a slave computer applies for the right to operate, or whether the slave computer automatically allocates the right to operate to the slave that first makes the application. Thirdly, if it is necessary to authorize an operator to have the right to operate, it can also use a password, or a password switch to lock the scope of the right to operate, to maximize the security of the system operation.

4) WF470 upgrade to WINCC

The upper computer software is upgraded from WF470 to WINCC, and the upper computer is upgraded to 15 inch touch screen operation mode.

With the powerful function of WINCC, the system has added the following functions:

(a) Mandarin/German language switching function to facilitate the daily operation of workshop operators and the regular maintenance of manufacturers;

B) Display the status of PLC input, output and analog input and output on the PC, which is consistent with the actual layout of the PLC module in the electronic control cabinet, and each point of each channel is accompanied by detailed notes;

Fig. 3 status display of PLC I/O module

C) Through the powerful storage function of WINCC, 100 sets of mold data management are added, and the technological parameters of the mold are stored in the mold formula beforehand, and the corresponding mold parameters are only exported during the production, which greatly improves the mold changing speed, improves the production efficiency and facilitates the unified management of the mold and reduces the misoperation.

Fig. 4 formulation of mold data

D) increase the operation authority management of mold data. After the system upgrade, the operator can only set the mold parameters up and down in the range of data derived from the formula, and the setting is invalid if it exceeds the range. Setting range can be set by machine tool maintenance personnel to reduce the damage to the mold caused by misoperation; increasing the height of the slider twice, integrating the data of the two adjustments into the mold formula, just click the button to realize the height setting, easy and comfortable operation; realizing the height of the slider and the air cushion adjustment at the same time, changing the mold operation. Fast and stable.

Fig. 5 parameter setting of mold data

E) super strong fault diagnosis system, adding operation information record. After the system upgrade, in addition to retaining the original fault records of the system, some important operations on the machine tool panel and all parameter setting operations for the mold are recorded, which is convenient for fault detection and clear responsibility.

Fig. 6 operation information record

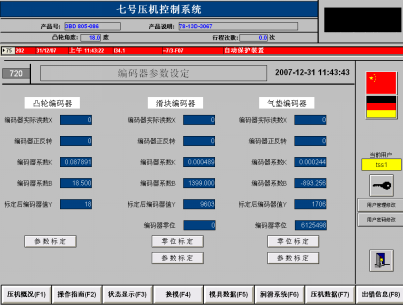

F) super system diagnosis function, increase encoder calibration, sensor and transmitter calibration. After the system is reformed, the complex calculation of parameter calibration is realized by program. In actual operation, the calibration can be accomplished only by directional guidance according to the calibration and by measuring the height or pressure, temperature and so on.

Fig. 7 encoder calibration

5) encoder is connected by PROFIBUS network

The encoder of the whole system is connected by PROFIBUS network, and the encoder of slider adjustment and air cushion adjustment is connected by a special PROFIBUS network. The cam encoder is connected by an independent PROFIBUS network, mainly considering that the electronic cam encoder is the core control of the press control system and has been running in the press. Fast real-time response is needed in the process. The maximum communication rate of PROFIBUS network can reach 12 Mb/s, which guarantees the encoder detection accuracy and communication quality.

Five, transformation effect analysis

1) safety aspects

S5 and S7 are used to run in parallel, and S5 is dismantled after confirming the reliability of S7 control system to ensure the risk-free transformation.

2) technical indicators

The key parameters of the press, such as slider, air cushion height, balancer and air cushion pressure, all meet the technological requirements, and the quality of the mold products is well controlled.

3) production efficiency

By introducing new formula technology and full Chinese operation, it can effectively increase the speed of mold change and reduce the intensity of work.

4) economic benefits

With the successful experience of the first press upgrade, the process of the press upgrade became more standardized, the period of the upgrade was shortened by one third, the high efficiency of the upgrade was achieved, and a lot of maintenance costs were saved. The SIEMENS compatible module of UNIMAT also saves cost.

Six, concluding remarks

Through this transformation, all the original control functions have been realized, and on the basis of the original operation monitoring functions, such as formula change, operation record query and other user-customized practical functions have been realized, which provides a powerful tool for the factory to carry out production management and accident analysis. At the same time, because S7 is more powerful than S5, both system response speed and maintenance and debugging have been greatly improved. Up to now, the system has been running safely and stably for more than half a year, and has been widely praised by factory operators and managers.