There is often some confusion between SCADA systems and HMIs because of their similarities.So let’s dive into HMIs now.

SCADA stands for“Supervisory Control and Data Acquisition”.It is used to monitor and control large areas,usually an entire site or plant.A SCADA system is a combination of many systems,including sensors,RTUs or Remote Terminal Units,and PLCs.The data from all these systems is then sent to a central SCADA unit.This SCADA unit has its own HMI.

This is why many people get confused and think that SCADA and HMI are the same thing.

The HMI or“Human Machine Interface”unit on a SCADA can monitor and control what it is connected to.In short,an HMI can be part of a SCADA,but a SCADA cannot be part of an HMI.

Simply put,let’s talk about the common use of HMIs.

While working at a water and wastewater facility,I came across a SCADA system.The HMI was located in the main water plant building,and this HMI was connected to the main SCADA unit of the water plant.Each booster pump station within the water district is shown on the screen,at each location there is a PLC connected to some sensors to monitor water flow pressure and other things,it is able to run and control the pumps themselves.Remote SCADA units are connected to the PLC system and allow operators to control and monitor each pump station from the main plant.

I am sure you can imagine how much time and labor a good SCADA system can save a company.Think of a SCADA system like a modern vehicle.You have several different sensors connected to different computers on the motherboard.Most of the internal functions,such as power seats,climate control and other things,are controlled by the BCM or Body Control Module.Most of your engine functions and sensors are monitored and controlled by the ECM or Engine Control Module.These modules all send information to the main screen in the dashboard for you to view and control through the driver controls(essentially your HMI).

An HMI is essentially a user control station,usually in the form of a touch screen or a screen with some buttons.They are usually associated with a machine or process.Most HMI applications tie the screen to a PLC that is compatible with it.Certain functions and sensors can be programmed to monitor and control the screen itself.

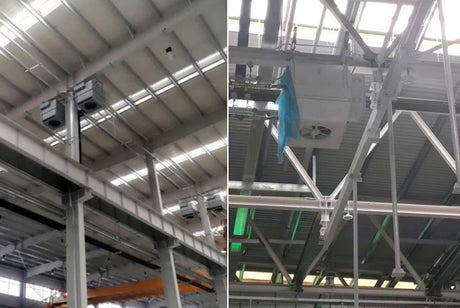

As can be seen from the above usage examples,HMI is a touch interface,which is a touch display screen of a single device.However,this type of display screen is affordable and has strong anti-interference ability,and can operate stably in industrial environments.

What are the characteristics of HMI?

First of all,HMI must be robust.In the field of industrial automation,devices with human-machine interface(HMI)are often in harsh and challenging environments.In order to meet these challenges and ensure its long-term reliability and performance,robustness is one of the necessary characteristics;

Secondly,impact and vibration resistance is also a necessary characteristic of HMI,especially for manufacturing workshops and mobile equipment,which can still operate normally without interference under continuous vibration and occasional shock conditions;

Finally,dust and water resistance,wide temperature design,support for Ethernet interface,and remote control are all characteristics of HMI;

Unimat has been focusing on industrial automation for 20 years.HMI is independently developed and supports free sample testing.It has high quality and beautiful price.If you have any needs for HMI,please contact Unimat.